Semiconductor Data Sheet Automation – Just The Way You Want It

Moore’s law prediction about the increase in density of an SoC design continues to prove accurate with each advancement of technology. But, along with this, a new complexity takes shape in the form of documentation for the advanced SoCs. Today, design engineers face the challenge of not only creating the design but also documenting it for internal and external customers. Documentation is the bane of every engineer. Frankly, it is fun to design a new product but the paperwork continues to be the most hated aspect of any project. And as they say, the project is not complete until the paperwork is done.

A good semiconductor data sheet increases the design value. It must contain everything, starting from the logical specification to details about the design architecture, including timing information and every subtle detail about the product. But, which member of the design team gets the honor to create the required documentation? We cannot ask a good writer, with no knowledge of the subject matter to write for us. Therefore, someone from the design team must take ownership of this task, which is often quite a challenge.

Imagine if you can get someone on the design team who is dedicated enough to do this required task in no time and at no additional cost. Or, how valuable would it be if there were a tool that could automate the entire datasheet creation process?

IDesignSpec’s (IDS) Datasheet feature is a solution to the semiconductor data sheet automation problem. It takes the design register specification and turns it into a datasheet automatically. It is a simple yet elegant solution. It preserves the original information from the specification and concurrently transforms it into a professional data sheet for different users, as depicted in this graphic.

![]()

Although the specification document created using IDesignSpec bears a resemblance to a Datasheet, however, there are several aspects of that format that require finesse to be a polished data sheet. Hence, a separate data sheet output was created. The datasheet output caters to the end-user requirements for information that originates in the specification, such as:

- Enabling the user to selectively include elements of the specification document.

- Filter out certain aspects of the specification document.

- Exclude specific proprietary information that should not be shared with the external world.

- Contain two or more versions or different types of information.

- Look more like a datasheet, rather an engineering specification.

- Select information from N number of specification documents programmatically and generate the datasheet.

- Easy to maintain and easy to change.

And many more capabilities.

Best of all these capabilities is the parameterized and object-oriented construction of datasheet output with IDesignSpec.

What does a parameterized data sheet mean?

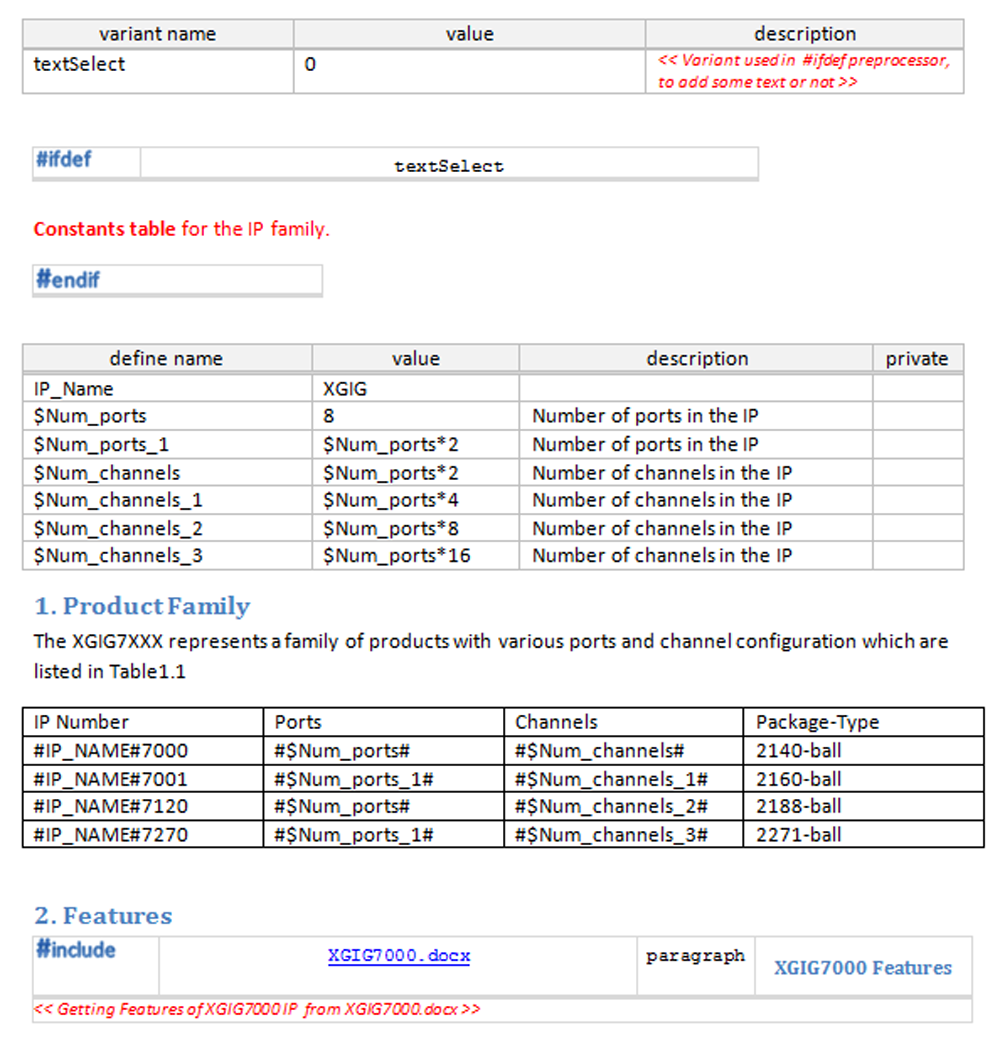

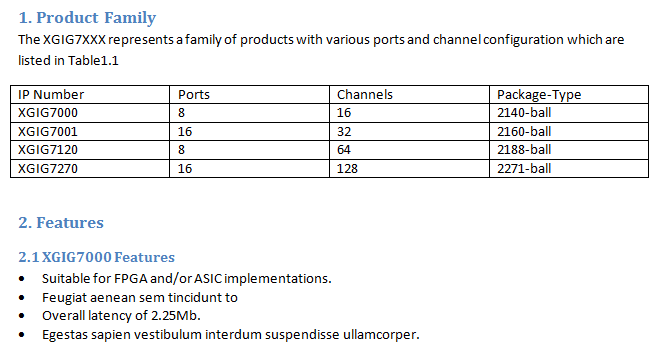

Today’s SoCs integrate a multitude of IPs which directly affects the complexity of the design and also influences its verification and documentation. Designers often create a parameterized design that changes its behavior based on the parameters defined. A parameterized design also requires a parameterized datasheet.

Consider a scenario where the Engineering team has to integrate all the IPs of a particular family into one datasheet document from individual datasheet files and vice versa. Copy-pasting could help them but with lots of wasted time and possibility of errors.

The IDS pre-processors and post-processors will serve as the best solution. Just define constants and parameters, add pre-processors like #include, and #ifdef, follow settings to remove the IDS define/variant templates, and generate the desired data sheet as shown in the example below:

There are numerous other features that automate the creation of semiconductor data sheets using IDesignSpec. We have created a short video that shows all these features in action. You can evaluate IDesignSpec to try out these special features and get perfect datasheets – just the way you want them.